Innovative Engineers – Boughtons of Bell Lane

This article was written by John Clutterbuck with the help of Richard Boughton, Alan Palmer, Adrian Graves and Vic French which is greatly appreciated

This is an account of Boughtons, a family company that started in agricultural engineering and developed many other areas of expertise. The company occupied premises in Bell Lane, Amersham Common, from the late nineteenth to the late twentieth century. By the 1980s, the company employed 500 people to make a wide range of engineering products, including waste management equipment, hydraulic winches, transmission systems, fire-fighting appliances and military equipment. The company was sold to a venture capital company in 1997 and subsequently relocated to the Midlands, ending links with the Boughton family and the Amersham area.

Thomas Trafford Boughton, the founder of TT Boughton and Sons, was born in 1874. His father, John Boughton, himself the son of Thomas Boughton, had married Kate Harper in 1871 and had moved to Chenies Manor. The family had previously come to Chenies from north Buckinghamshire. John Boughton farmed extensively in the local area and ran the village flour mill on the River Chess. He held the Manor and the farm from the Duke of Bedford, who owned most of Chenies village in addition to the Manor.

As Thomas Trafford Boughton (later known as TTB) grew up, he was enterprising and fascinated by engineering. He preferred to work at the flour mill rather than in farming. He imported, assembled and sold McCormick binders and mowers from the US, which were revolutionising the harvesting of cereal crops.

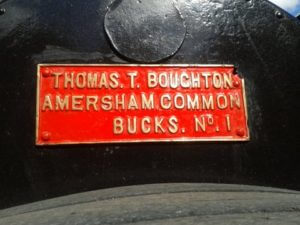

In 1897 John Boughton purchased a Fowler steam traction engine at the Royal Counties Agricultural Show, Reading. This became known as Black Jack and the village turned out for its arrival at Chenies. John Boughton presented his son Tom with Black Jack and a threshing set and the agricultural engineering and contracting company of T T Boughton was created. Black Jack is still going strong after lengthy restoration and appeared in Amersham on Heritage Day 2016, providing a link between the town and the foundation of T T Boughton nearly 120 years ago.

The new firm of T T Boughton worked on the family farm at Chenies and on neighbouring farms. Further steam traction engines were acquired and the business expanded to include work on the roads for Amersham Rural District Council.  Tom showed his creative ability by developing and patenting a folding hay sweep in 1902. Here he is shown with the hay sweep at Chenies Manor at the start of the twentieth century.

Tom showed his creative ability by developing and patenting a folding hay sweep in 1902. Here he is shown with the hay sweep at Chenies Manor at the start of the twentieth century.

The Duke of Bedford was opposed to industrial activity at Chenies. He made it clear to John Boughton that, unless the industrial activity was removed from the village, the family would be given notice to quit. Tom did not want to move far, as the majority of his workforce lived within walking distance of Chenies. John Boughton acquired two acres of land from Lord Chesham in Amersham Common to the west of Bell Lane (formerly known as Colmans Lane).

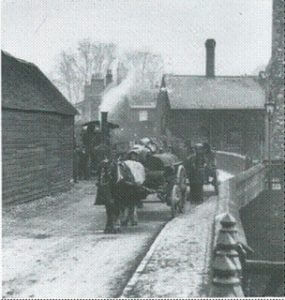

There were hazards associated with the use of steam traction engines in the early 1900s, as these two photos demonstrate: the first shows an engine in White Hill Chesham. The second photo shows the frailty of a canal bridge when confronted by the weight of a steam traction engine.

There were hazards associated with the use of steam traction engines in the early 1900s, as these two photos demonstrate: the first shows an engine in White Hill Chesham. The second photo shows the frailty of a canal bridge when confronted by the weight of a steam traction engine.

In the mid 1900s, John Boughton persuaded the railway company to extend the sidings at Chalfont and Latimer station so that thousands of tons of horse manure could be brought by rail from London stables for use as fertiliser in many nearby farms. It was the company’s first venture into waste handling. Train loads of manure were brought from London to Chalfont and Latimer station as bowler-hatted commuters travelled in the opposite direction on the newly opened Metropolitan Line.

The impact of the railway reduced the need for threshing in what became the London suburbs of Ealing, Hanwell, Hayes, Harrow, Pinner, Northwood and Ruislip. As the threshing business contracted, the need to clear land for housing and to install roads in the new suburbs increased. The company sold 12 traction engines in 1921, but retained Black Jack.

The economic depression of the 1930s brought hard times. Councils cut back on road maintenance and road rollers were laid up. Boughtons sought out whatever opportunities they could, including clearing land for construction of airfields as the threat of war increased, and pumping work on foundations for pylons to assist Pirelli in the construction of the electrical grid in the Thames Valley.

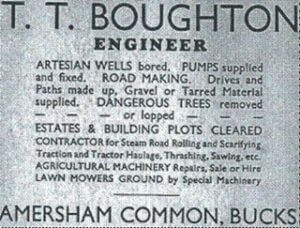

The company placed the following advertisement in the local edition of Kelly’s Directory in the 1930s and 1940s:

By the start of the Second World War, the founder of Boughtons, Thomas Trafford Boughton had passed over the running of the company to his sons, Trafford and John. In the 1980s, John Boughton published two books about the company, “Steam in the Veins” and “Triumphs of Transport”. The following section on the War and the post-War period is largely based on these books, which are sources for many of the pictures.

At the start of the War, many of Boughtons’ activities became subject to government oversight. The agricultural division, run by John Boughton, reported to the government’s Country Agricultural Committee, while the transport division, run by Trafford Boughton, reported to the “Home Grown Timber Department” of the Board of Trade. Much of the War was spent in balancing the needs of the wartime government against demand from farmers for threshing and other services.

It was clear that Boughtons would need to expand dramatically to meet both government and civil requirements. Timber extraction plant, equipment to drain boggy land and steam traction engines were acquired from various locations around the country. Steam traction engine drivers were brought out of retirement. Boughtons’ skills at improvisation and invention came to the fore.

John Boughton was called up for military service in 1939. His father, who was of “advancing years and indifferent health”, had taken over John’s company duties, but it became clear that John’s input to the company was essential. He was released from military service. The Cheshire Regiment, which he had been due to join, was part of the rearguard action to protect the Dunkirk evacuation. Many of the Cheshires were killed or captured.

Although the 1939 harvest had been large, creating much work for the company, there were national concerns over the vulnerability of food imports to submarine warfare. Grassland and drained moorland were put to the plough in 1940, effectively doubling the cereal harvest. John Boughton noted that “The Women’s Land Army was formed and pensioners were encouraged to return to the industry to help as much as possible and to train newcomers in the arts of rick building, thatching and other essentials.” … “Much of the threshing was carried out by steam and it was labour intensive.” His sister Joan was given the job of looking after three hundred Land Girls in Buckinghamshire, many of whom were new to the countryside.

The company received many timber contracts of highest government priority, including that for felling beech woods on the Latimer Estate. Much military equipment had been lost at Dunkirk. Local sawmills were required to produce rifle butts. Boughtons had to acquire timber haulage equipment such as diesel lorries, steam traction engines and winches. The picture shows Dancer & Hearn’s sawmills in Penn Street, where timber was converted into rifle butts and, later in the War, wings for Mosquito aircraft

The company received many timber contracts of highest government priority, including that for felling beech woods on the Latimer Estate. Much military equipment had been lost at Dunkirk. Local sawmills were required to produce rifle butts. Boughtons had to acquire timber haulage equipment such as diesel lorries, steam traction engines and winches. The picture shows Dancer & Hearn’s sawmills in Penn Street, where timber was converted into rifle butts and, later in the War, wings for Mosquito aircraft

In 1943, the range of Boughton’s threshing operations expanded into Hertfordshire, servicing the needs of nearly a thousand farmers in a thousand square miles of territory. New equipment, such as threshers and balers, in short supply in the early years of the war, became available in 1944, as did tractors imported from the US. Boughton’s fleet was partly modernised. In 1945, the company began its successful development of a range of winches for attachment to tractors and other vehicles. By the mid 1950s, there were over 90 different versions of the Boughton winch, with sales at home and abroad.

When the War drew to a close, the company’s agricultural fleet was still predominantly steam powered. Two years later, it was all diesel powered. With the transition to peacetime came changes in agricultural practices. By 1950, combine harvesters had replaced the separate activities of threshing and binding. Traditional agricultural activities were replaced by crop spraying with fertilisers. The company’s post-war employees included demobbed ex-servicemen and former German prisoners of war who had stayed in England.

In the post-war period, Bovingdon airfield was used as a base for the agricultural side of the business until closed by planning authorities. The manufacturing business in Bell Lane prospered and three satellite factories were opened in Devon, including Winkleigh, which had been a wartime airfield. The company became involved in overseas trade after the War. A large plough and a traction engine were sent to east Africa to help with the ill-fated groundnut scheme. John Boughton demonstrated a six-tonner stream traction engine to a representative of the Argentinean government and several were bought for use in transporting coal in Argentina.

The 1950s and 1960s saw considerable expansion and diversification. Using the skills and experience developed during the War, Boughtons became adept at modifying vehicles and providing working attachments, such as grabs, hoists and winches for the forestry industry. The product range later expanded to include cranes, oil-drilling equipment and all-wheel-drive conversions for commercial chassis. Specialist vehicle manufacture for the military market became an important activity.

The company was involved in developing new ways to handle waste and materials for the building industry as part of its innovative programme to provide working attachments to vehicles. A 1960s Boughton-Marrel skip loader fitted to a Bedford truck. The first skip loader was produced in 1956. This led to the development of a range of waste handling and compaction vehicles and equipment over the next forty years. In the 1960s, the company was a founding member of the Container Handling Equipment Manufacturers Association, which was formed to establish industry standards.

The company was involved in developing new ways to handle waste and materials for the building industry as part of its innovative programme to provide working attachments to vehicles. A 1960s Boughton-Marrel skip loader fitted to a Bedford truck. The first skip loader was produced in 1956. This led to the development of a range of waste handling and compaction vehicles and equipment over the next forty years. In the 1960s, the company was a founding member of the Container Handling Equipment Manufacturers Association, which was formed to establish industry standards.

Boughtons responded to the motorway construction programme in the 1960s and 1970s by developing load-bearing “dollies” for transporting large reinforced concrete beams, as shown in the picture. The success of the company in overseas markets was recognised by the award of the Queen’s Award for Export Achievement in 1977. The company’s employment peaked at around 500 in the 1980s.

Boughtons responded to the motorway construction programme in the 1960s and 1970s by developing load-bearing “dollies” for transporting large reinforced concrete beams, as shown in the picture. The success of the company in overseas markets was recognised by the award of the Queen’s Award for Export Achievement in 1977. The company’s employment peaked at around 500 in the 1980s.

The range of the company’s products continued to expand and develop in the 1990s, when exports accounted for nearly 40% of turnover. The photo gallery below shows examples of products for environmental engineering and military sytems. and transport such as converting a US Marines Oskosh truck to handle ISO containers, ribbon bridges and combat support boats. Comments from the US Marine Corps on the Oskosh project were extremely positive: “All comments from the field have been nothing less than laudatory. The dedication exhibited by your team serves as an example worthy of emulation and I can honestly say that it has been an absolute pleasure with such a professional firm. On behalf of the United States Marine Corps and Marine Systems Command, my sincere appreciation for a job truly well done.”

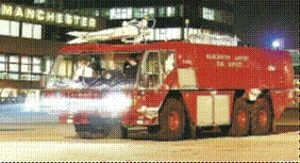

The company became involved in airfield crash tenders after the introduction of the Boeing 747 in the late 1960s. They developed the Griffin chassis, named after an Amersham pub. The crash tender based on this chassis had a high capacity for delivering water and foam. Its design won the 1974 Design Council Engineering Award. Orders came from airports around the world. The company’s next chassis was the smaller Pegasus, designed to travel quickly over rough ground. The vehicle in the picture is a Barracuda fire tender from the 1990s. A company brochure from the 1990s stated that Marlin and Barracuda crash tenders were becoming “standard in international airports around the world”.

The company became involved in airfield crash tenders after the introduction of the Boeing 747 in the late 1960s. They developed the Griffin chassis, named after an Amersham pub. The crash tender based on this chassis had a high capacity for delivering water and foam. Its design won the 1974 Design Council Engineering Award. Orders came from airports around the world. The company’s next chassis was the smaller Pegasus, designed to travel quickly over rough ground. The vehicle in the picture is a Barracuda fire tender from the 1990s. A company brochure from the 1990s stated that Marlin and Barracuda crash tenders were becoming “standard in international airports around the world”.

Click on any of the photographs below to enlarge it and to see the description. Then click on forward or back arrows at the foot of each photograph. To close the pictures, just click on one.

In 1997, the company encountered cash flow problems at the time of a credit squeeze and was sold to a venture capital company, marking the end of the connection with Boughton family. By April 2011, Reynolds Boughton Ltd and Reynolds Boughton (Devon) Ltd were in administration. These companies were acquired by the Skan Group in May 2011 and become known as Boughton Engineering Ltd. The headquarters and assembly operations were relocated to Wolverhampton in October of that year and the fabrication facility was relocated from Winkleigh to Bideford in 2013.

In a separate development, a new company, Ulrich Attachments Ltd started work on 8 Oct 1998 to continue work on winches, buckets and other attachments for cranes and vehicles such as tractors. Ulrich Attachments have an assembly facility located in Aylesbury and a manufacturing plant in Hull.