The story of Amersham International / GE Healthcare growth from producing radium compounds in WW2 to creating global healthcare products

This article was written by John Clutterbuck and the images are courtesy of GE Healthcare. John acknowledges much help from Conor McKechnie (Communications Director, Life Sciences), Roger Pickett (R&D 1975-2011) and Matthew Morrison (R&D).

2015 marks the 75th anniversary of the start of radiochemical production at Chilcote House, White Lion Road, Amersham. The site, owned by GE Healthcare since 2004, has grown from producing radium compound for luminous paint with very few staff in 1940 to a major organisation with a huge range of products for medical, industrial and domestic use, selling in global markets. GE Healthcare is the largest employer in the Amersham area. When production started at Chilcote House, it was part of the war effort. Further links with the Second World War came with the acquisition of Pollards Wood, with its associations with SOE and MI5.

Thorium Ltd – 1940 to 1950

At the start of the Second World War, radium was urgently needed to make luminous paint. In 1940, a shipment of radium concentrate, en route from Portugal to Germany, was confiscated in the London docks. Thorium Ltd, a company set up just before the First World War to break the German monopoly on thoria for gas mantles, was producing luminous paint for the defence establishment. The company was chosen to process the confiscated shipment of radium concentrate. Richard Bennett, general manager of Thorium Ltd, recruited Dr Patrick Grove from Johnson Matthey to be chemist in charge of radium extraction.

Grove and Bennett searched the area north and west of London, looking for premises less than 30 miles from central London with good access to Thorium’s offices in Wembley. They stopped for refreshments at the White Lion public house in Amersham and asked if there was a building nearby called Chilcote House. “Next door”, they were told. Chilcote House and grounds were bought by Thorium Ltd for £2,000. By May 1940, Dr Grove was in residence at Chilcote House and the labs were up and running.

Grove and Bennett searched the area north and west of London, looking for premises less than 30 miles from central London with good access to Thorium’s offices in Wembley. They stopped for refreshments at the White Lion public house in Amersham and asked if there was a building nearby called Chilcote House. “Next door”, they were told. Chilcote House and grounds were bought by Thorium Ltd for £2,000. By May 1940, Dr Grove was in residence at Chilcote House and the labs were up and running.

Dr Walter Patrick Grove CBE had a fundamental influence on corporate and technical developments from the start in 1940 until his retirement in May 1979. He died in 1986, aged 71.

Dr Walter Patrick Grove CBE had a fundamental influence on corporate and technical developments from the start in 1940 until his retirement in May 1979. He died in 1986, aged 71.

As autumn 1940 approached, Dr Grove was able to see evidence of progress. He visited one of the labs in the evening and “to my immense satisfaction was visible a whole series of beakers whose contents were glowing in the dark with radioactivity – varying in colour from bright blue at the top end to a vague white in the lower stages. It was quite unexpected and the impact on me must have been almost as great as it was on the Curies 40 years earlier when they saw the phenomenon for the first time.”

The first consignment of radium bromide, to be used for making luminous dials and gunsights for ships and aircraft, had been produced by October 1940. Amid nearby explosions of jettisoned bombs, the Chilcote team transferred the pure radium bromide to glass capillaries which were put into lead pots and lowered in a bucket down a 40ft shaft in the front garden. By 1944, Chilcote House had refined 35 grammes of radium with high efficiency; some 500 kilogrammes of luminous compound was produced on site. Chilcote was also producing radioactive material for academic laboratories and neutron source for determination of neutron yield in uranium fission.

Chilcote House was purchased from Thorium Ltd by the Ministry of Supply in 1946. Thorium Ltd was appointed to manage on an agency basis what had now become the “national centre for the processing and distribution of radium, radon and artificial radioactive substances for scientific, medical and industrial purposes.” Additional land was acquired and laboratories were built.

Radiochemical Centre – 1949 to 1982

The name was changed to The Radiochemical Centre in 1949. The number of staff had grown from a handful in the war years to 70. The press were invited. The Bucks Examiner reported: “In part, the veil was lifted on one of the curiosities of our district, which has set tongues a-wagging”. In 1950, the Radiochemical Centre became an outstation of the Atomic Energy Research Establishment at Harwell. Thorium terminated its contract.

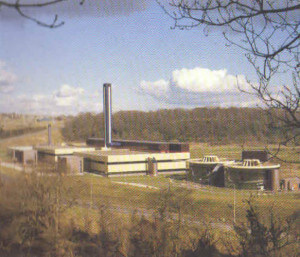

The country’s first specifically designed buildings for production of isotopes for medical and industrial uses were opened in 1954. The Centre’s products were now being exported to forty countries. The Centre became a focus for press and

A series of booklets were produced by Amersham International (the name used after 1982) in 1990 to mark the company’s fiftieth anniversary. The booklet on the 1950s quotes a writer, Lee Armour, who described an “atomic war” being fought by a handful of men in the English countryside … “a war against disease and a fight to wrest from nature some of her deepest secrets”. The booklet continued: “In medicine, isotopes and radium-based appliances benefited therapy, diagnosis and research, helping the search for improved techniques in radiotherapy and diagnosis. At the Radiochemical Centre, invaluable pioneering work was done on producing organic compounds using carbon-14, undoubtedly the most widely applied radioisotope in research; with a half-life of more than 5,000 years, its concentration and radiation intensity remain virtually constant for the period of an experiment. Some 200 carbon-14 labelled research chemicals were synthesised and the first tritium labelled chemicals were introduced; and the biosynthesis of vitamin B12 with cobalt-58 was developed. The Fifties also saw radioactive isotopes coming into wide use in industry, for instance using beta and gamma rays in the continuous control of thickness in sheet products such as paper and plastics; in checking packaged products to maintain desired content levels and as a static eliminator on production lines.”

As an enhanced safety measure, a building with enclosures to enable operators to manipulate radioactive materials remotely was opened in 1957. In the same year, the UKAEA made the Radiochemical Centre into a single comprehensive organisation for the production and marketing of radioisotopes, a role shared with Harwell for the previous nine years. By 1957, the Centre’s annual sales had exceeded £1 million for the first time, medical accounting for 50% of deliveries, 15% for industry and 35% for research activities.

The 1950s edition of the 50th anniversary booklet shows the unloading of a consignment of Amersham’s radioisotopes from the wingtip of a BOAC Bristol Britannia. Such consignments were routinely carried in the wingtips of passenger airliners from London in the 1950s. Wingtip containers obviated the need for heavy shielding.

The 1950s edition of the 50th anniversary booklet shows the unloading of a consignment of Amersham’s radioisotopes from the wingtip of a BOAC Bristol Britannia. Such consignments were routinely carried in the wingtips of passenger airliners from London in the 1950s. Wingtip containers obviated the need for heavy shielding.

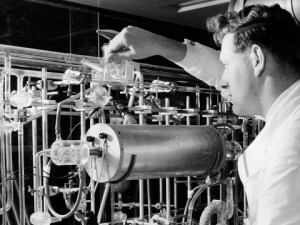

By 1960 there had been a considerable expansion on the Amersham site and new laboratories were built to accommodate the increasingly important carbon 14 and tritium chemical labelling work. Here, a chemist works with tritium purification apparatus in the laboratories. The 1960s saw strong growth in the Centre’s product range and financial performance. At the start of the decade, the Centre at Amersham had nearly 1,000 catalogue items – more than 530 labelled compounds and more than 330 sources of beta, gamma and neutron radiations. Exports consistently accounted for 60 per cent of sales. At an event in 1965 to mark the Centre’s silver jubilee, Dr Grove stated that the number of catalogue items had risen to 2,000. There were 20,000 users throughout the world, with sales amounting to £1.9 million. The Centre provided employment for around 450 people.

By 1960 there had been a considerable expansion on the Amersham site and new laboratories were built to accommodate the increasingly important carbon 14 and tritium chemical labelling work. Here, a chemist works with tritium purification apparatus in the laboratories. The 1960s saw strong growth in the Centre’s product range and financial performance. At the start of the decade, the Centre at Amersham had nearly 1,000 catalogue items – more than 530 labelled compounds and more than 330 sources of beta, gamma and neutron radiations. Exports consistently accounted for 60 per cent of sales. At an event in 1965 to mark the Centre’s silver jubilee, Dr Grove stated that the number of catalogue items had risen to 2,000. There were 20,000 users throughout the world, with sales amounting to £1.9 million. The Centre provided employment for around 450 people.

In its Silver Jubilee year, the Centre launched the world’s first commercial RIA (radioimmunoassay) kit, for measuring the insulin level in the blood of diabetics. This precise and sensitive technique became a universal assay tool, particularly in clinical endocrinology. The Radiochemical Centre led the scientific and commercial development of radioimmunoassay.

In its Silver Jubilee year, the Centre launched the world’s first commercial RIA (radioimmunoassay) kit, for measuring the insulin level in the blood of diabetics. This precise and sensitive technique became a universal assay tool, particularly in clinical endocrinology. The Radiochemical Centre led the scientific and commercial development of radioimmunoassay.

In its early beginnings, the Centre had made use of the radioactive qualities of radium, a naturally occurring element, to enable production of luminous paint. Within twenty five years, the Centre had expanded its range of functions and products to include a wide range of tailor made radioactive isotopes. The Centre had become a base for modern alchemists who transmuted mundane raw materials into precious substances for medical and industrial use.

The Centre installed the world’s first commercial cyclotron at Amersham in 1966. Prior to this, nuclear reactors had been the main source of isotope production for the Centre. The cyclotron, which was followed by two more in later years, was also the first to be designed and operated solely for isotope production. The cyclotron performed well, becoming the source for isotopes such as sodium-22, cobalt-57, arsenic-74 and cadmium-109.

The Centre installed the world’s first commercial cyclotron at Amersham in 1966. Prior to this, nuclear reactors had been the main source of isotope production for the Centre. The cyclotron, which was followed by two more in later years, was also the first to be designed and operated solely for isotope production. The cyclotron performed well, becoming the source for isotopes such as sodium-22, cobalt-57, arsenic-74 and cadmium-109.

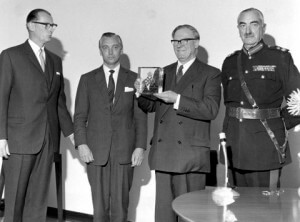

In 1967, the Centre received the first of fourteen Queen’s Awards, for Export Achievement, and for Technology. The Lord Lieutenant of Buckinghamshire, Brigadier Sir Henry Floyd, presented the Queen’s Award for Export Achievement to the Centre’s Chairman, Lord Penny, in the presence of Dr W P Grove and Sir John Hill. The Centre’s overseas marketing technique was unusual but effective. The Centre’s scientists travelled the world as Technical Liaison Visitors, advising customers and helping them to use the Centre’s products. This approach led to further orders and was so successful that export sales comprised a high proportion of turnover.

In 1967, the Centre received the first of fourteen Queen’s Awards, for Export Achievement, and for Technology. The Lord Lieutenant of Buckinghamshire, Brigadier Sir Henry Floyd, presented the Queen’s Award for Export Achievement to the Centre’s Chairman, Lord Penny, in the presence of Dr W P Grove and Sir John Hill. The Centre’s overseas marketing technique was unusual but effective. The Centre’s scientists travelled the world as Technical Liaison Visitors, advising customers and helping them to use the Centre’s products. This approach led to further orders and was so successful that export sales comprised a high proportion of turnover.

The Centre’s building expansion programme continued throughout the 1960s, with an additional 15.000 sq ft of productive space for organic and inorganic laboratories. The Centre, a world leader in its field, produced “The Radiochemical Manual” a guide for professional users of radioactive substances. On 1 April 1971, The Radiochemical Centre became a limited company, with Dr Patrick Grove as Managing Director. The first report showed sales of £6 million, 62% of which were export. By the mid 1970s, staff numbers had risen to 1,000 and sales were in “double figure millions of pounds”. Gloucester Laboratories were established in 1976.

This photo shows the freeze-drying unit (1976) for preparing non-radioactive components of in vitro diagnostic products.

This photo shows the freeze-drying unit (1976) for preparing non-radioactive components of in vitro diagnostic products.

Cardiff Laboratories opened in 1980 with Dr John Maynard as its first general manager. In October 2001, Cardiff Labs, now a centre for life sciences research and manufacturing, was renamed The Maynard Centre in recognition of John Maynard’s achievements during 40 years of service with the company.

Amersham International – 1982 to 2004

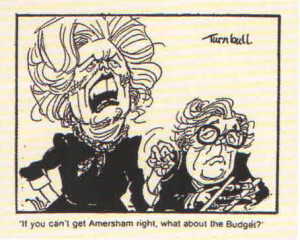

In 1982, The Radiochemical Centre Ltd was renamed Amersham International Ltd. On 17 February 1982 the company became the first Thatcher Government privatisation, as Amersham International plc.

Shares were floated on the London Stock Exchange on 24 February, offered at 142p. The issue was 24.6 times oversubscribed and the price rocketed 48p in seconds, increasing the company’s value from £71m to £95m. As with many subsequent privatisations, the sale of Amersham international was not without controversy. Some on the left of politics were opposed to the idea of selling off state owned companies. Others felt that the share price had been pitched too low.

Shares were floated on the London Stock Exchange on 24 February, offered at 142p. The issue was 24.6 times oversubscribed and the price rocketed 48p in seconds, increasing the company’s value from £71m to £95m. As with many subsequent privatisations, the sale of Amersham international was not without controversy. Some on the left of politics were opposed to the idea of selling off state owned companies. Others felt that the share price had been pitched too low.

In “The Official History of Privatisation – The Formative Years 1970-1987”, David Parker, Emeritus Professor of Privatisation and Regulation, Cranfield University, says “Amersham International … was a specialist producer of radioactive chemicals and was initially part of the state-owned atomic energy industry. From 1971 it was run as an independently managed company, while maintaining some close operating links with its former parent, the UK Atomic Energy Authority. It employed around 2000 people. Of these, 1000 worked at its head office and manufacturing site at Amersham in Buckinghamshire and 400 in Cardiff, which contained about half the manufacturing operations. The remainder were employed at subsidiaries in the US, Germany, France, Australia, the Netherlands and Belgium.

“The Centre operated in the internationally competitive manufacture of radioisotopes for use in medicine, industry and research, exporting around 80 per cent of its output. The main customers were hospitals and pharmaceutical companies and certain other specialist manufacturers in Europe and America. Sales growth was typically around 30 per cent per annum and turnover in 1980/1 was over £80 million. The enterprises achieved profit margins in the region of 15 – 23 per cent. In the words of the Parliamentary Under-Secretary of State at the Department of Energy, John Moore, TRC ‘was an extremely successful organisation.’ It was an obvious candidate for privatisation, being likely to prove attractive to private investors. It was not considered inefficiently run in the state sector.” …“(E)ach eligible employee was offered 35 free shares and one free share for every one purchased, up to 350 shares per employee. Ninety nine per cent of employees became shareholders in the company.”

By the mid-1980s, staff numbers had grown to 3,000. The value of the company’s assets had risen to £100 million. Research and Development continued at a high level, accounting for 10% of sales. In addition to the new factory at Cardiff, a Group HQ building was opened at Amersham Place, Little Chalfont. In 1985, premises were added at Pollards Wood for non-radioactive technology.

In August 1997, Amersham International formed a joint venture with Pharmacia and Upjohn to form Amersham Pharmacia Biotech. Shortly afterwards Amersham International merged with Nycomed of Norway to form Nycomed Amersham plc. This was a strategic alliance, merging Amersham’s radioactive imaging products (radiopharmaceuticals) with X-ray contrast media and ultrasound contrast agents from Nycomed.

The pharmaceutical business of Nycomed (Nycomed Pharma) was outside that portfolio and was sold in 1999, following which the company was renamed as Amersham plc. The financial aspects of the sale of Nycomed Pharma, finally completed in 2001, raised more than £400mn. Amersham plc issued a statement on completion of the sale referring to the significant cash inflow from the sale and from operating cash flow, debt had been reduced to £70m, leaving the company well placed to invest in its core businesses of in-vivo diagnostic imaging and life sciences. The statement said that the company had annual sales of £1.4bn and around 8900 employees worldwide.

Pollards Wood and World War ll

The independent website, Amersham.org.uk, has an entry on Pollards Wood, noting that it was “requisitioned in 1941 and became ‘Special Training School XX’ of the Special Operations Executive, better known as SOE and popularised by the Sebastian Faulks novel ‘Charlotte Gray’ and the film of the same name. STS20 was apparently used to train Polish section SOE agents. The Polish SOE activities included operation WILDHORN in 1944 and 1945 in which British / Polish aircraft were covertly landed to bring out key Polish underground / resistance leaders and return them to England.”

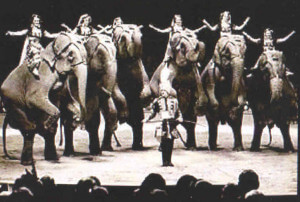

In the 1930s, Pollards Wood House was bought by the circus owner Bertram Mills. After the death of Bertram Mills in 1938, the circus was taken over by his sons, Bernard and Cyril, but closed down in the Second World War, when the animals were kept in the grounds of the house. Several local residents later recalled having seen strings of elephants en route from the station during the War, each holding the tail of the one in front with its trunk. Caravans and trailers had to be scattered in the woods, so that they could not be seen from the air. It is reported that, in 1940, over thirty horses from the circus grazed on the cricket pitch in Shardeloes Park. Amersham International accquired Pollards Wood House in 1985. After extensive remodelling, it was opened as GE Healthcare’s headquarters in 2007

In the 1930s, Pollards Wood House was bought by the circus owner Bertram Mills. After the death of Bertram Mills in 1938, the circus was taken over by his sons, Bernard and Cyril, but closed down in the Second World War, when the animals were kept in the grounds of the house. Several local residents later recalled having seen strings of elephants en route from the station during the War, each holding the tail of the one in front with its trunk. Caravans and trailers had to be scattered in the woods, so that they could not be seen from the air. It is reported that, in 1940, over thirty horses from the circus grazed on the cricket pitch in Shardeloes Park. Amersham International accquired Pollards Wood House in 1985. After extensive remodelling, it was opened as GE Healthcare’s headquarters in 2007

It is reported that Cyril Mills served in MI5 in the War, and that he was the spymaster who controlled Juan Pujol Garcia, codenamed “Garbo”. However, it is reported elsewhere that Pujol’s handler was Tomás (Tommy) Harris; the confusion may arise from the fact that Cyril Mills and Tommy Harris were jointly responsible for the positive vetting of Pujol on behalf of MI5. It was Mills who apparently chose Garbo as Pujo’s codename, after Greta Garbo. Irrespective of the precise details of Pujol’s British Secret Service reporting relationships, he was a remarkable double agent, perhaps uniquely having been awarded an MBE by the British and an Iron Cross by the Germans. Pujol played an important role in Operation Fortitude, a deception which convinced the German High Command that the 1944 invasion of France would take place in the Pas de Calais region rather than in Normandy. In 1984, Pujol, who had been living in Venezuela after faking his own death in Angola, came to London. He was reunited at the Special Services Club with some of his former MI5 colleagues, including Cyril Mills.

GE Healthcare – 2004 to date

Amersham plc was acquired by General Electric for £5.7bn in 2004. GE traces its beginnings to Thomas Edison’s Electric Light Company, which became the General Electric Company in 1892. GE is the only company listed in the Dow Jones Industrial Index today that was also included in the original index in 1896.

The acquisition created GE Healthcare which became the first GE business with headquarters outside the US. Based at Pollards Wood and with revenues of approximately £11.5bn, GE Healthcare is a leading global healthcare technology and services company, employing more than 50,000 people in more than 100 countries. The Grove Centre remains an important centre of research, development and manufacturing for GE’s diagnostic imaging agents, as well as the global headquarters of GE Healthcare’s Life Sciences division. With revenues in the region of £2.5bn, the business helps researchers, pharmaceutical companies and clinicians develop, manufacture and use drugs, vaccines and biological medicines.

In February 2005, the work of the Grove Centre in White Lion Road was commemorated by the the Royal Society of Chemistry with the award of Historical Chemical Landmark status. The RSC stated in 2005 that ‘The major centre for the development of medical and industrial applications in the UK over the past 60 years was selected for its pioneering work in the war on life-threatening conditions.’

Every week, about a million patients around the world have medical scans enhanced with GE imaging agents so doctors can make more accurate decisions. About 90% of US FDA-regulated biological medicines, as well as 94% of the world’s insulin, is manufactured using GE equipment. Developing biological medicines relies on a deep understanding of complex biology. Research tools from GE Healthcare help scientists study cells, genes and proteins, helping them understand the biological basis of diseases and guide the development of drugs to treat them. The company’s customers range from academic institutions to pharmaceutical companies and hospitals developing the latest therapies.

GE Healthcare continues the heritage of the Grove Centre at the forefront of medical research, helping doctors detect, diagnose and manage diseases such as cancer, heart disease and dementia. For example GE Healthcare is helping to uncover the causes, risks, and effects of Alzheimer’s disease, and is collaborating with pharmaceutical companies to help develop therapies for Alzheimer’s and other dementias. The company is also pioneering the development of new technology for the rapidly growing fields of regenerative medicine and cell therapy, which have the potential to change the face of modern medicine. Researchers combine biology, chemistry and physics into materials, devices, systems and therapeutic approaches that augment, repair, replace or regenerate diseased organs and tissue, essentially helping the body to heal itself.

GE Medical Systems Ltd are now based in Nightingales Lane, Chalfont St Giles

Diagnostic Imaging; Life Care Solutions; Ultrasound

Diagnostic Imaging Services

Healthcare Digital